A groundbreaking collaboration between Cameco and Saskatchewan Polytechnic is transforming uranium mining at the Cigar Lake operation in northern Saskatchewan.

The two-year applied research project, launched in 2020, optimized the jet boring system used to extract ore from deep underground deposits. Led by Sask Polytech's Digital Integration Centre of Excellence (DICE), the research combined hands-on mining expertise with advanced machine learning. While the formal project has ended, its impact continues to grow.

Cameco retained all intellectual property developed during the applied research project and has since integrated the machine learning models into its operations. Nathaniel Kozicki, a former DICE researcher, now works at Cigar Lake as a mine engineer, continuing to refine and apply the technology.

Kozicki played a pivotal role in the initial applied research project, bridging the gap between mining and computer science. As a geological engineer with coding experience, he helped translate complex mining data into machine learning models. His cross-discipline expertise was essential in identifying relevant data and ensuring accuracy.

During the pilot project the DICE team visited Cigar Lake to gain deeper insight into mining operations and the jet boring system. The machine learning model was built from these insights, along with billions of data points, including geological features, sensor readings and historical mining data, to develop a more efficient jet boring system and user-friendly machine learning application.

Jet boring uses high-pressure water to carve cavities in uranium ore bodies. By applying machine learning, DICE and Cameco refined the process adjusting variables like water pressure, timing and jet rotation to improve efficiency.

"Testing at Cigar Lake showed increased ore recovery and reduced waste, highlighting the technology's potential," says Dr. Terry Peckham, DICE director and research chair. "It's something both DICE and Cameco are proud of."

One of the most significant breakthroughs came through improved cavity design. Previously, engineers relied on past experience and comparisons with nearby ore cavities to plan new mining zones, a time-consuming and uncertain process. The machine learning system analyzes all historical cavity data to generate optimized designs in minutes.

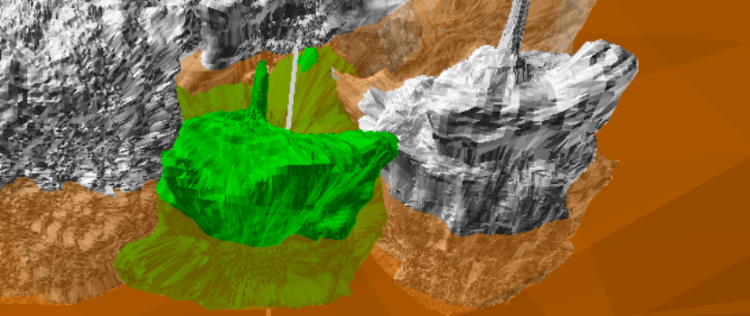

Screen shot from of one of the mining cavities

"What used to take a half day to plan now takes 15 minutes," Kozicki says. "It's become a standard tool in our operations at Cigar Lake. This is incredibly valuable information for our team."

DICE projects like this also serve as an important training ground for future industry leaders. "One of the benefits of DICE is its ability to provide students and recent graduates with hands-on experience through applied research projects. These opportunities allow them to develop expertise in machine learning and AI, gain experience and expertise, and bring this knowledge into industry," says Peckham.

"I have an uncommon skillset, there aren't many mining engineers who know how to code," Kozicki says. "This kind of cross-disciplinary experience opens doors and helps Cameco maintain these machine-learning tools in-house."

While machine learning is a powerful tool, both Cameco and Sask Polytech stress that it complements, not replaces, human expertise.

"It's not magic," Kozicki says. "It doesn't eliminate the need for skilled workers. It replaces the tedious parts of the job and helps Cameco make better decisions, faster."

As the models evolve, Cameco is exploring real-time responsiveness, potentially allowing adjustments while mining is underway. With Cigar Lake licensed to produce 18 million pounds of uranium annually, even a one-per-cent improvement in recovery could have a significant impact.

The project's success is timely. As global demand for clean energy grows, Saskatchewan's uranium sector is under the spotlight. Machine learning is emerging as a key driver of innovation, helping the province remain competitive in a rapidly digitizing industry.

"This isn't just about a product," Peckham says. "It's about advancing knowledge, training talent and positioning Saskatchewan as a leader in mining innovation."

DICE provides innovative solutions for solving data and digital challenges for business, industry and non-profits. By partnering with DICE, organizations have access to outstanding computational facilities, faculty expertise, and talented student researchers, along with research and development funding and a vast network of connections.

The two-year applied research project was partially funded by the Natural Sciences and Engineering Research Council of Canada (NSERC). Mitacs and International Minerals Innovation Institute (IMII) provided funds for multiple student internships.

Learn more about collaborating with DICE at saskpolytech.ca/dice.