Saskatchewan Polytechnic's Research in Additive Manufacturing and Prototyping (RAMP) team has designed and built a customized testing device for cutting bits, through funding from the National Research Council's Industrial Research Assistance Program. The RAMP team was contacted by Bit Service, a Saskatchewan company that manufactures cutting bits for potash mining. They were looking for a way to test the bits in-house before shipping to clients. Prior to the creation of the testing device, Bit Service sent their cutting bit products to Alberta for testing.

Bit Service CEO Scott Bahr, a Sask Polytech Mechanical Engineering Technology alumnus, says his experience as a student influenced how he runs his business.

"There was a lot of direct access to industry to help prepare students to work in an industrial environment in a much quicker fashion," he says. "We've hired several alumni that are currently working with the company. Hiring a Sask Polytech graduate gives you greater confidence that they bring a higher level of practical preparation."

To improve research and development and increase operational efficiency, Bahr wanted testing to be performed in-house before shipping and integration into mining operations. To do so, the Bit Service team needed equipment that would provide insight into the effectiveness of a bit by performing abrasion testing.

The RAMP lab is one of the specialized applied research facilities in the Sustainability-Led Integrated Centres of Excellence (SLICE) at Sask Polytech. Partners collaborating with the facility gain access to the latest tools, equipment and expertise to improve production methods and test new ideas.

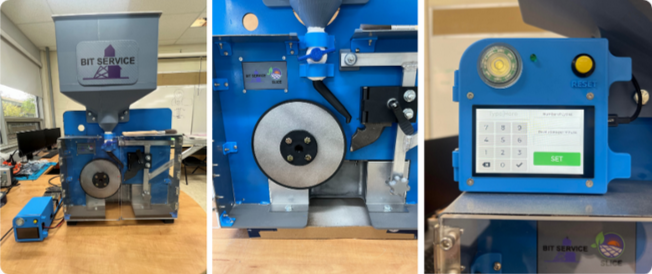

The machine created through the project is an automated system that precisely pours abrasive sand onto a contact point between a rotating rubber wheel and the bit under test. After the test period completes, the bit is removed and visually inspected for wear and can be weighed to calculate how much material was removed during the test.

Ann Quimado, RAMP research associate, was the primary designer of this mechatronic project. She worked with the client, collaborated with colleagues and leaned on help from students in the welding program to put the purpose-built machine together.

"Our projects are unique. There's not one that's similar to another," she says "It helps to have a client with a clear vision. When we fully understand what the client's needs are, we can go from there."

Quimado created 10 versions of the sand delivery nozzle to ensure the flow rate met industry testing standards. Electromagnetic interference caused the digital display screen to go blank. The team eventually solved the problem by separating the screen from the motor.

"Like any good project this one had challenges, but we had great communication with the client and informed them of issues and progress," says RAMP research chair Leon Lipoth. "Bit Service is a wonderful company with which to work. They're a Saskatchewan success story."

The opportunity to work directly with clients is vital in ensuring a successful outcome. Bayo Emmanuel, continuous improvement engineer at Bit Service, worked with the RAMP team throughout the project.

"We were really impressed with the team's dedication in expanding the project to meet our specialized needs and in developing the equipment. The experience was really, really good for us," he says.

Overall, the project took seven months to complete. Bit Service has been using the tester for the last two months.

"The equipment was customized for us. Testing is cost-effective, repeatable and meets industry standards," says Emmanuel. "The machine is new and innovative and allows us to simulate real mining experiences."

SLICE is based in Sask Polytech's Faculty of Technology and Skilled Trades. SLICE's vision is to advance sustainability in Saskatchewan and beyond through collaborative applied research for the benefit of our economy, environment, society and future generations.

Learn more about applied research at saskpolytech.ca/research.

Learn more about Bit Service at bitservice.ca.