Precision spraying is being reimagined with a smart technology upgrade.

Dr. Medhat Moussa, professor in the Department of Electrical and Computer Engineering, College of Engineering, together with industry partners, has developed an automated agricultural robotic system to help farmers manage weeds in lima bean crops.

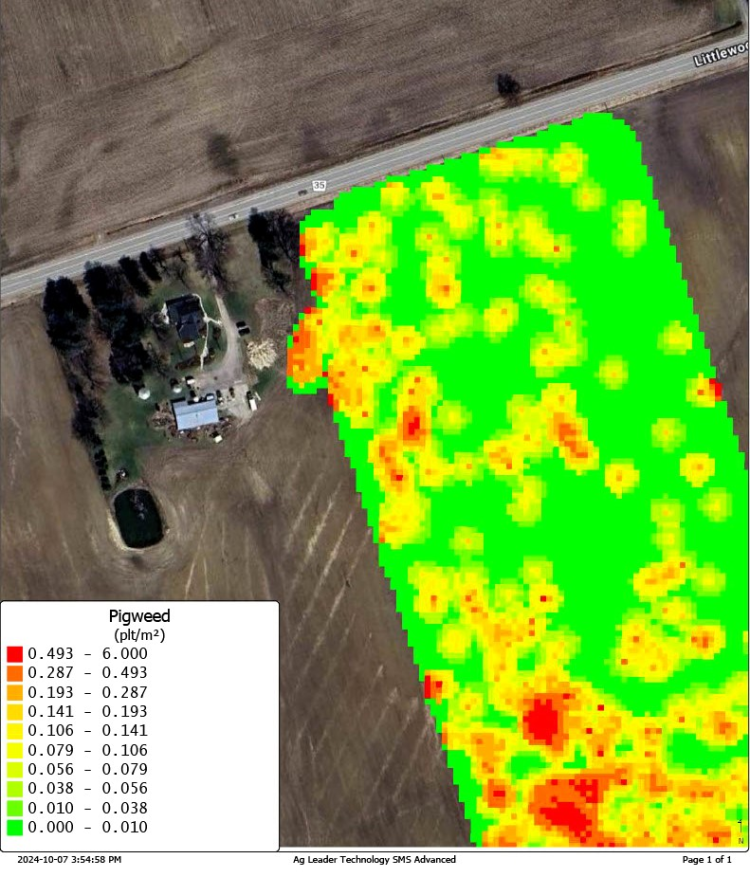

Developed at the Robotics Institute at Guelph, the technology is a tractor attachment that uses computer vision and artificial intelligence (AI) algorithms to scout for weeds. The system generates weed density maps of entire fields that can be used to create precision application plans for chemical herbicides. These maps guide farmers in applying herbicides only where needed, saving time, reducing chemical use and cutting costs.

Better weed removal ultimately leads to healthier crops, higher quality yields and lower production losses.

"Our system enhances traditional weed mitigation that farmers are familiar with by allowing them to do it much more efficiently," says Moussa. "It makes the scouting process faster and more precise than manual methods at a more affordable price point compared to other solutions."

Automating the weed scouting process

Weed scouting is an important part of crop management. If left to grow, weeds can contaminate crops, reduce production yields and leave behind seeds that affect the next year's harvest. They can also become resistant to herbicides, making it hard to get rid of them.

Powered by AI algorithms, weed density maps are used for precision application plans for herbicides saving time, energy and chemical use

Traditionally, farmers walk through fields and check random sections for weed-dense areas. But this process is time consuming and susceptible to human error, especially since it's done early in the season when weeds are small and easy to miss.

Farmers also only look at fractions of a field and estimate needs for the rest of the crop based on those samples. The system developed by Moussa and his team provides a more complete picture.

"Our robotic attachment, equipped with cameras, gets mounted onto a small tractor or similar vehicles," says Moussa. "As the tractor is driven through the field, the cameras scan the ground and take photos that are analyzed by a three-stage AI algorithm. Our algorithm differentiates between lima beans and weeds in each image, then combines the images into a complete density map showing exactly which areas need to be treated."

Moussa says the technology strikes a balance between fully autonomous robotic weeders and traditional manual practices. While the attachment can be mounted onto self-driving vehicles, it's primarily designed for tractors driven by humans.

"There are weeding robots out there that operate entirely on their own, but they're not being widely adopted because they are either very expensive or very slow," says Moussa. "Our goal is to take the first step towards enhancing the existing technology so that it's more easily accessible to farmers."

Building on U of G's robotics expertise

Dr. Medhat Moussa

Moussa and his team are partnered with Nortera Foods, a fruit and vegetable producer and end user of the system, and Haggerty AgRobotics, a leader in the agriculture robotics and automation industry, to bring this technology to Ontario farms and beyond. The collaboration is an example of a practical agricultural robotics solution championed by the AgRobotics Working Group.

"Our lab has been working in the automated agriculture space for years using technologies such as computer vision and machine learning," says Moussa. "It's a great fit because our partners have the capabilities to test our technology on a larger scale, show it to farmers and bridge the gap to market adoption."

The system's design builds on the lab's ag-robotics expertise. Last year, they developed a self-operating tomato-picking robot, Guelph Intelligent Greenhouse Automation System (GIGAS), which uses different but similar vision and algorithms.

The technology is in its final stages of field testing and has potential to be adapted for use in other crops in the future.

When asked what excites him most about the technology, Moussa highlights two things: the training opportunities for students involved in the project and seeing the everyday impacts of his team's work.

"As a university researcher, I'm always looking to bring what our team is doing out into the real world," he says. "We publish our papers and do the academic work, which is all important, but getting to benefit industry, consumers and the Canadian economy in general is what really excites me. We need to keep bridging the gap between the lab and the real world."

The development of the robotic weed scouting prototype required the collection of images of various weeds in different open fields and growing conditions. During the summer of 2023, several fields were used for data collection, including the Ontario Crops Research Centre in Elora, which is owned by the Government of Ontario through its agency, Agricultural Research and Innovation Ontario, and managed by the University of Guelph through the Ontario Agri-Food Innovation Alliance.

The project is also supported by funding from the Ontario Centre of Innovation, and industry partners Haggerty AgRobotics and Nortera Foods.