New research out of the University of New Brunswick may make aluminum smelting more efficient and sustainable while also creating a source of green, zero-carbon fuel and supporting sectors that rely on aluminum materials. This new closed-loop, low-energy aluminum digestion process is a promising step in decarbonizing the aluminum industry and toward creating an environmentally sustainable future.

New research by UNB chemistry professor Dr. Barry Blight could revolutionize how we deal with aluminum refining waste, aluminum recycling and even fuelling our world reducing how much material ends up in landfills and making our future more sustainable.

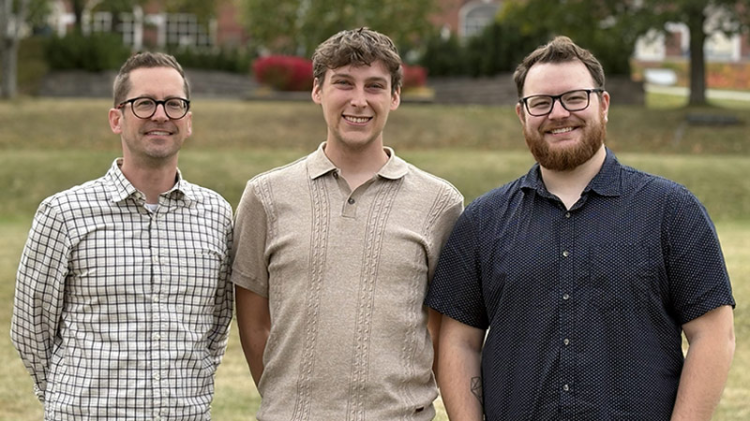

The findings are detailed in a paper authored by Dr. Barry Blight, professor of chemistry at UNB, Dr. Mason Lawrence, NSERC postdoctoral fellow and graduate student Robbie Horne. The article was published in August in the journal RSC Sustainability.

Blight had been presented with a challenge: Current processes for smelting aluminum leave a lot of waste material called "dross." Could something useful be done with it?

Dross contains significant amounts of aluminum that isn't captured by the smelting process, along with other materials including silicates and metals like iron, magnesium and manganese. In Canada alone, the industry generates an estimated quarter million tonnes of dross a year; globally, that number is estimated to be closer to 5.3 million tonnes a year.

Current methods for extracting more aluminum from dross, let alone other materials, are costly, requiring expensive equipment, a significant amount of energy, or both. Because of this, much of this potentially valuable material is simply discarded, ending up in landfills.

Based on the results of Blight's new research, however, this could soon change.

The research suggests that rather than ending up in landfills, dross could instead be used to cleanly produce trillions of litres of hydrogen gas, as well as commercially valuable compounds like high-purity aluminum oxide, which is also used in aluminum smelting, as well as by industries as diverse as pharmaceuticals, cosmetics, fire retardants and chemical production.

The process has also been modified to yield a special, porous type of material called "metal organic frameworks" or MOFs. These MOFs have been a major research focus for Blight's team, and can be used to store hydrogen, capture carbon, harvest water, or in some cases even to help neutralize chemical weapons.

(Did you know? The 2025 Nobel Prize in Chemistry was awarded to three researchers, Susumu Kitagawa, Richard Robson and Omar M. Yaghi, for their groundbreaking discoveries in developing these metal-organic frameworks!)

Because of the way the process works, it forms a closed-loop catalytic system, where the valuable materials are generated without breaking down the catalyst the elements used to trigger the reaction. The process sustainably generates hydrogen gas and several aluminum materials at a much lower energy cost than currently used methods.

As is often the case, this research breakthrough didn't happen spontaneously and independently.

Blight's team had been working on new applications for some of his past research to the production hydrogen gas from water through photocatalysis, a process that uses light energy to make a chemical reaction occur where it otherwise would not.

In UNB's office of research services, the research and innovations partnerships team had become aware of a chemical digestion-based aluminum refining technique, which they brought to Blight as a potential interest.

Chemical digestion takes matter and breaks it down into component molecules through exposure to particular substances, like how the human body breaks down food. This aluminum technique had existed for some time, but had not been commercially viable, nor was it fully developed.

And, just like a successful chemistry experiment, bringing these two ideas together ended up creating just the reaction they were hoping for.

By integrating this prior research and development into his ongoing work, Blight's team was able to improve on the digestion process. This improvement makes it more efficient and complete, while generating clean hydrogen. They also expanded the process to purify aluminum oxide and to create metal-organic framework material.

The project has continued to pick up speed since, successfully receiving funding for a postdoctoral fellowship and additional research, identifying novel, potentially valuable intellectual property and partnering with industry towards commercialization and other sector needs.

"We are really excited about how this research translates to industry applications, and to creating a greener future," said Blight. "We've identified a sustainable, circular economy for this industrial waste, turning it into energy and useful materials. We are now exploring the use of waste and salvage aluminum as source materials for these processes, and hope to develop a recycling site right here in New Brunswick."

This research has been financially supported by ResearchNB.